Design

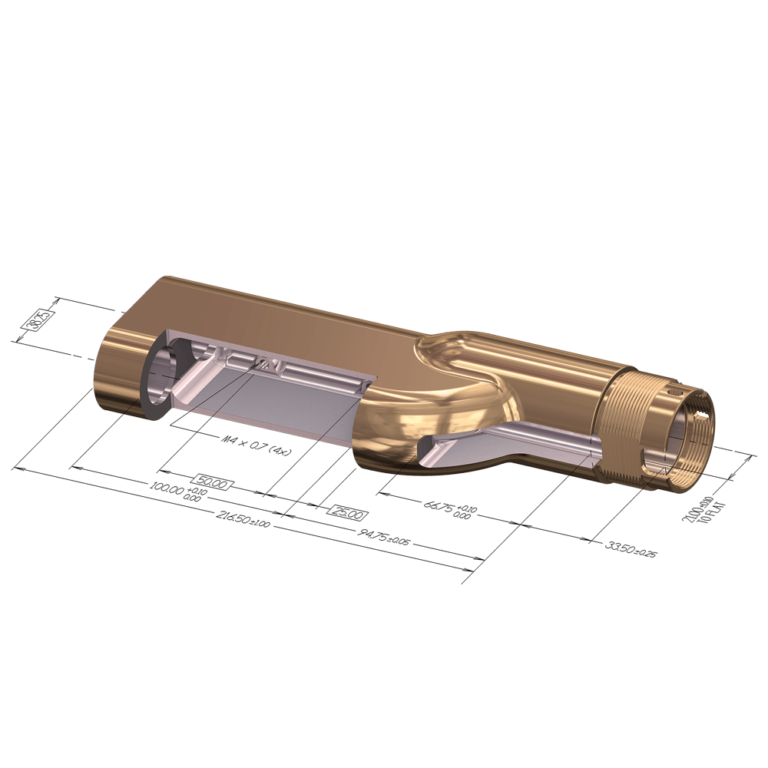

Mastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Design is included with Mastercam’s Suite of CAM solutions. It is also available as a standalone product.

From fixing flaws in an imported model, to creating fixtures for work holding on a machine-and so much more, this powerful CAD engine includes modeling and prep tools for CAM programmers to get parts on and off machines quickly.

- Comprehensive CAD platform.

- Direct modeling, file import functionality, and model prep.

- CAD for CAM supports production efficiency.

A notable advantage of our integrated CAD for CAM is the ability to import files from virtually any computer-aided design source. Mastercam includes a large selection of CAD model importers, so no matter where a model was created, you can import and modify as needed for your machining purposes.

- Mastercam can read CAD files from ASCII, CADL, DWG, DXF, EPS, IGES, Inventor (IPT, IDW, IAM), KeyCreator Files (CKD), Parasolids, Rhino 3DM, SOLIDWORKS (SLDPRT, SLDASM, SLDDRW), SAT (ACIS solids), Solid Edge (PAR & PSM), SpaceClaim Files (SCDOC), STEP, STL, and VDA.

- Specialty data translators are available to read CAD files from UG/NX, CoroPlus®, Creo, and CATIA™.

- Full 3D CAD modeling.

- Import, create, and manipulate wireframe, surfaces, STL, and solids data.

- Mastercam Art makes it possible to work with files including JPG, TIFF, and raster-based images—and create a 3D relief based on user preference.

Connect Now for Support

If you have any doubts, need guidance, or require assistance, click the link below

Features

Robust CAD

A comprehensive suite of tools for the creation/import and editing of models to modify and prepare for machining.

Direct-Editing Solids

This suite of tools found on the Model Prep ribbon allows you to modify solids that have no history to edit. You can select faces of a solid body to change the length, you can modify the radius of fillets or remove them all together. You can select bosses or cavities and move them, copy them, or eliminate them entirely.

Drafting

Dimensions, labels, and notes are part of our drafting functionality to communicate important design information to the shop floor.

Wireframe

Includes everything you need for the creation and editing of lines, arcs, splines, and points. Beyond 2D sketch creation, 3D capabilities offer unlimited flexibility to create the geometry you need with ease.

Surfaces

Surface modeling is an excellent way to create, edit, and display shapes from simple surfaces of revolution to complex organic shapes that cannot easily be done with wireframe. Mastercam gives you a powerful set of surface design tools for straightforward control over every detail of your work.

Free Software

Give the world’s #1 CAM software a test drive. Download Mastercam Demo/Home Learning Edition at no cost. Use it to learn Mastercam and get familiar with the latest advances in CAD/CAM – every step of the way up to actually machining a part!

Localized Support

Our Mastercam Resellers bring years of practical experience specific to various regions, manufacturing goals, and language requirements worldwide, to ensure that as a Mastercam user, you always have the support you need to get the most out of your CAD/CAM investment.

History-Based Solids

Allows you to construct models from the simplest wireframe sketches and to continue to edit the model to meet your desired result. These functions create a sequential history of individual operations that can easily be edited as required and update downstream operations automatically. These functions offer a great amount of flexibility for future change.

System Requirements

Click here to see minimum and recommended system configurations for Mastercam. These recommendations are based on systems we have in use at Mastercam for testing and evaluation purposes. Our recommendation is to get as much power (processor, video card and memory) for your systems as you can afford.

Frequently Asked Questions

Computer-aided manufacturing (CAM) software is used in design to produce prototypes and production parts. Using a software like Mastercam, parts that are created in design software are prepared for machining. The CAM software generates the toolpaths that control a CNC machine to cut or 3D print parts to the specifications of the design.

From design through the manufacturing process, CAD and CAM increase productivity with digital solutions that help designers apply their creative and technical expertise. The limits of what CAD can be used to design is truly the human imagination.

CAD/CAM software is used in the design industry because the technology enables rapid prototyping and iterative design processes. Using CAD/CAM, you could reach a production run in the time it once took to create blueprints.

CAD/CAM software is used in product design to bring digital flexibility and automation to design and manufacturing processes. The use of these technologies brings speed and efficiency to product design that can reduce the barrier to the market and improve the chances of successful market introduction as a result of digital iteration and rapid prototyping.

Computer aided design software, called CAD, can be used to design everything from industrial production parts to art installations to everyday items you will find in your home. CAD is used to design parts for cars and the transportation industry, lifesaving parts and devices in the medical field, numerous components in the aerospace industry, and much more.