Swiss

You no longer need a separate software package for CNC Swiss machines — something programmers and machinists appreciate. Give your shop the convenience and precision of Mastercam Swiss Machining Solutions for gang-style machines and select gang-turret and B-axis machines.

Our Swiss Solutions combine Mastercam Mill and Mastercam Lathe, with an optimized post processor to give you a reliable set of tools to program parts for your Swiss machines—exactly how you need them.

- This bundle of technology delivers precision G-code and the flexibility to standardize your shop with a single software package to program a wide variety of Swiss machines.

- Provides enhanced POCO (Pick-Off Cut-Off) strategy.

- Includes multi-stream NC program viewing.

- Customized Swiss posting options allow for more accurate G-code programming.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data.

Programming in the Lathe product provides easy roughing, grooving, threading, parting, drilling, boring, and tapping. You can also perform milling operations with Mastercam’s proven toolpaths such as Contour, Drill, Dynamic Motion, OptiRough, Pocket, and Project for increased productivity. Mastercam Lathe also delivers a set of C-axis programming, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling, and cross contour and drilling.

More people use Mastercam than any other CAM software. From CAD inception to the creation of a final machined part, Mastercam is designed as a comprehensive solution for manufacturing efficiency.

- Easily add machine options and custom code to post output

- Use existing Mastercam Mill or Mastercam Lathe knowledge to quickly produce Swiss programs

- Maintain program uniformity throughout your shop

- Intelligent, stock-aware toolpaths

- Robust 3D solids and surface machining

- Complete tool library and custom tool support

- Flexibility to swap programmed part to different machine makes and models

Connect Now for Support

If you have any doubts, need guidance, or require assistance, click the link below

Features

Efficiency

You are provided with customized parameters directly within Mastercam for lathe stock advance, specific machine setup parameters, expandable custom machine options, and user-specified options.

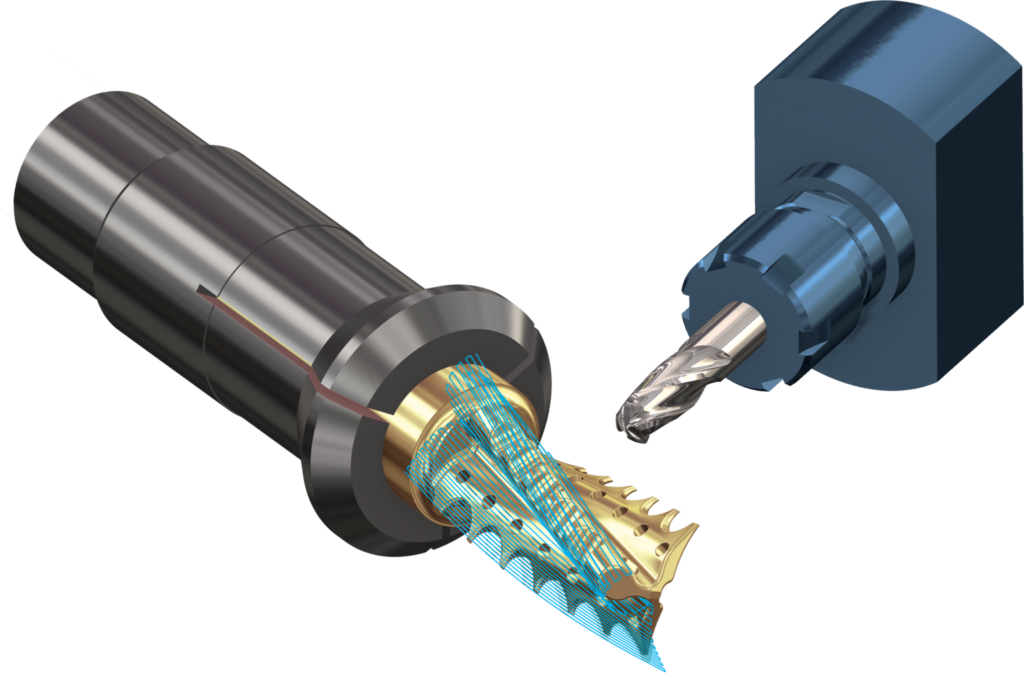

Live Tooling

Machine any job with the combined power of C- and Y-axis machining.

Multi-Stream Program Viewing with Sync Codes

Mastercam Swiss Solutions deliver a simple and effective way to get clean, proven G-code.

Powerful CAD

Open any CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Localized Support

Our Mastercam Resellers bring years of practical experience specific to various regions, manufacturing goals, and language requirements worldwide, to ensure that as a Mastercam user, you always have the support you need to get the most out of your CAD/CAM investment.

Dynamic Motion

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

System Requirements

Click here to see minimum and recommended system configurations for Mastercam. These recommendations are based on systems we have in use at Mastercam for testing and evaluation purposes. Our recommendation is to get as much power (processor, video card and memory) for your systems as you can afford.

Frequently Asked Questions

Swiss machining is a specialized type of CNC machining that utilizes a sliding headstock, collet, and guide bushing. This enables machining of very accurate and sometimes very small parts, due to how close the cutting tool is located to the cutting portion of the material, typically less than 3mm away. The close proximity of tool tip to stock allows for very fast and accurate cycle times.

A Swiss CNC machine combines a sliding headstock (material moves) and a combination of turning and milling Tools. Both static and live tools can be found on Swiss CNC machines. They are capable of drilling, threading, grooving, gear hobbing, thread whirling, slitting saws, broaching, and other forms of metal removal. The proximity of tool tip to stock allows for very fast and accurate cycle times.

A Swiss machinist is a skilled worker who specialized in operating Swiss CNC machines. Swiss machinists should have good working knowledge of multitasking machines and part-specific processes. These skilled workers must be proficient in both milling and turning operations and typically have a creative, “think outside the box” mentality.

A Swiss-type lathe is a Swiss CNC machine combining a sliding headstock (material moves) and a combination of turning and milling tools. Both static and live tools can be found on a Swiss-type lathe. They are capable of drilling, threading, grooving, gear hobbing, thread whirling, slitting saws, broaching, and other forms of metal removal. The close proximity of tool tip to stock allows for very fast and accurate cycle times.

A conventional CNC turning center typically moves turret-mounted tools or a B-axis head toward the stationary stock, whereas a Swiss-type turning center moves the sliding stock into stationary tools. That being said, many Swiss turning centers have the ability to do both types of machining, with turrets and B-axis heads, making Swiss-type machines very versatile.